Characteristics

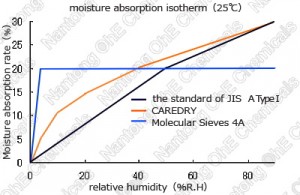

It has a strong ability of absorbing moisture at low humidity environment, especially under 40% RH, it can proof corrupt of metals effectively. The moisture-absorption rate is higher than the requirement of Japan Industry Standard( JIS-Z-0701).

It is a physical absorptive desiccant. After absorbing the moisture, it has no distortion caused by deliquescence. Contacting with water, it has no heat generated. It contains little water-soluble substances and the PH value of it is 7~8, almost neutral, so it will cause no corrosion to the metal.

As its raw material, clay is natural mineral and does not contain environmental management substances and meets RoHS.

Moisture-absorption rate

| Item | Our company | JIS-Z-0701 | |

|---|---|---|---|

| Moisture-absorption rate(%) | 20%RH | 14.5 | 8.0 |

| 50%RH | 21.5 | 20.0 | |

※The above-mentioned are not guarantee value but standard value.

Composition

| Item | Weight ratio(%) |

|---|---|

| SiO2 | 70.0 |

| Al2O3 | 20.0 |

| MgO | 5.0 |

| CaO | 3.0 |

| Fe2O3 | 1.0 |

| K2O | 0.2 |

| Ig-Loss | 1.0 |

※Data is the Standard Value, not the Guarantee Value.

Packaging Material

| Type | Packaging material |

|---|---|

| CAREDRY BMB | It is dust-free desiccant and meets TYPEⅠ&Ⅱ of U.S. Military Specification(MIL-D-3464). Using smooth and high strength non-woven fabric as surface and special blended non-through-hole PE non-woven fabric in the back, it can prevent the dust going through. |

| CAREDRY CT | CT type is enclosed in nonwoven fablic that is able to endure hard handling as like the export packaging and preservation of heavy load, etc. As dust-free desiccant, it meets TYPEⅠ&Ⅱ of U.S. Military Specification(MIL-D-3464). |

| UNITPAK BF | Three layers: Nonwoven fabric/MPF/PE and is controlled for optimal moisture permeability. Ink does not contact with products directly since it is the back side printing, and paper powder is not scattered because paper is not used. |

| UNITPAK BD | Use high bacteria blocking tyvek film, it is suitable for IT related clean workshops. |

※:Tyvek is the brand of Du Pont USA.

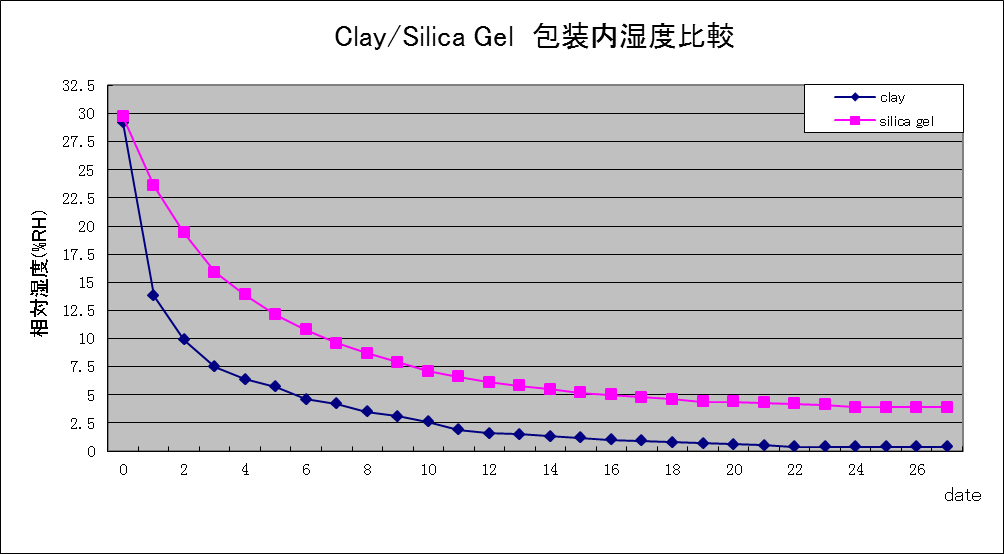

Test of inner package humidity

Pack the silica gel and clay each 30g with the same packaging material and then put into the aluminum foil bag with 10pcs of QFP tray. Filling data recorder to measure the humidity inside the bag. At the end of the test, the equilibrium moisture in the aluminum bag sealed silica gel is 3.8% while clay sealed one is 0.1%. In the area of low humidity, the moisture absorption capacity of the clay desiccant is superior to that of silica gel.