Characteristic

Create antibacterial deodorant by coating B type silica gel with antibacterial metal ion through our special technology. Almost no dissolution and gasification, it has antibacterial and mildew proof effect to the contact surface for a long time.

Antibacterial metal ion is a type of antibacterial agent taking silver – sub zinc ion as main component. It has a wide range of antimicrobial spectrum, inhibits the reproduction of bacteria and prevents foul smell caused by bacteria.

Anti-bacterial mechanism

Antibacterial metal ion spreads to microbial proliferation, attacks protein of cell membrane and cuts off the combine. Oxygen in the antibacterial agent turns to active oxygen partly through the antibacterial metal accelerant. The active oxygen has a strong antibacterial effect like ozone and hydrogen peroxide. And it can diffuse into the cells, disruption of protein composition and kill microorganisms.

Use

Use as deodorant for pet toilet and simple toilet.

Spec

We can customize plastic bottle, plastic film, bulk or other special shape. Please consult with our company.

Attention

Do not pour into the toilet and sewer.

Safety

Antibacterial metal ion does not contain harmful heavy metals. High security of it has been confirmed by acute oral toxicity test, single dose skin irritation test, variation gene test and the skin feeling test. It is base on antibacterial agent approved by Environmental Protection Agency (EPA) USA.

The chemical formula of silica gel is stable SiO2+nH2O, it has superior safety and it is considered as food additives by American FDA. Main component silicon dioxide will not be absorbed in the body. Even if it is taking by accident, human will not be poisoned.

Absorption test

Test method

Taking 8ml of ammonia (about 14 ~ 15%) and seal into 30cm angle aluminum gas barrier packaging materials. Fill in air to total 4000ml. Place in a 25℃ constant temperature room for 24 hours and 7% concentration of ammonia is generated. Seal 3gram of each samples by non-woven film with good air permeability well ventilated (melfit5x10cm). Then sealed into angle aluminum gas barrier bag (15×12.5cm) and exhaust the rest air in the bag. Inject 250ml of ammonia with a concentration of 7%.Test the gas concentration after 1, 5, 10, 15 minutes by detector tube method. Take the gas filled point concentration as 100% and use the concentration at each minute as odor rate by %.

The ammonia residual rate (%)

| Test material / Time | 1 minute later | 5 minute later | 10 minute later | 15 minute later |

|---|---|---|---|---|

| B type silica gel made in Japan | 12.86 | 0.49 | 0.87 | 0.51 |

| Ceramics activated carbon | 31.43 | 35.71 | 20.00 | 14.29 |

Seal 30cm trim ethylamine standard liquid into angle aluminum gas barrier packaging materials to form gas of 220ppm concentration. Seal 3gram of each samples by non-woven film with good air permeability well ventilated (melfit5x10cm). Then sealed into angle aluminum gas barrier bag (15×12.5cm) and exhaust the rest air in the bag. Inject 200ml of 220ppm concentration trim ethylamine gas. Test the gas concentration after 1, 5, 10, 15 minutes by detector tube method. Take the gas filled point concentration as 100% and use the concentration at each minute as odor rate by %.

Odor rate of trim ethylamine (%)

| Test material / Time | 1 minute later | 5 minute later | 10 minute later | 15 minute later |

|---|---|---|---|---|

| B type silica gel made in Japan | 7.0 | 0.50 | 0.15 | 0.00 |

| Ceramics activated carbon | 16.7 | 11.69 | 0.91 | 1.04 |

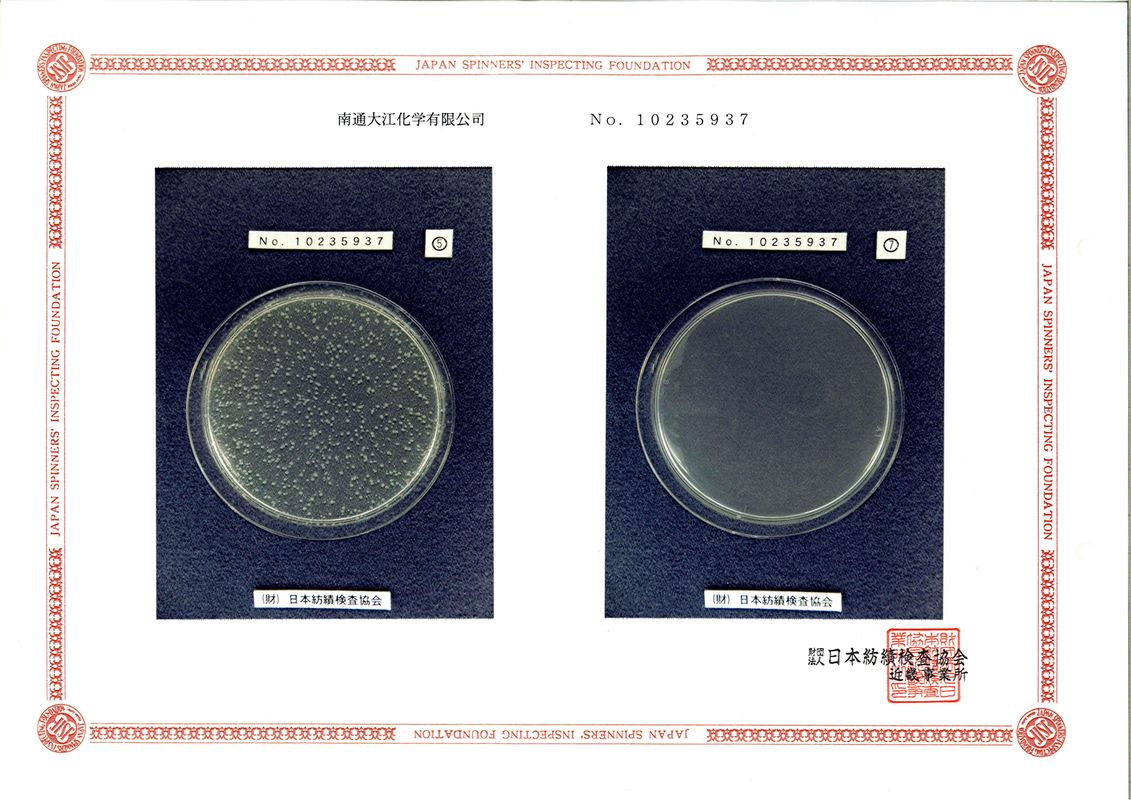

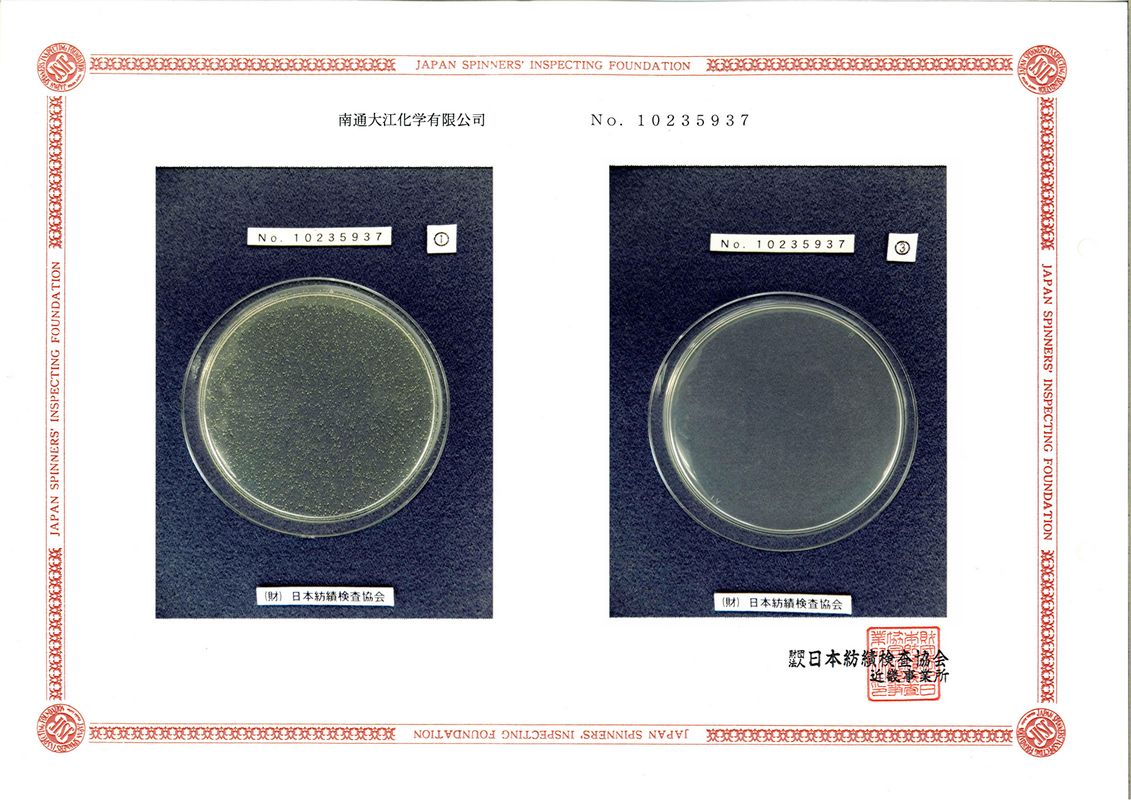

Effect confirmation test(Test by Japan third party test organization)

|

|

||||||||||||